Demand & Capacity Planning

JSC offers capabilities and pragmatic tools for mid- to long-term planning of demand, capacity requirements, and demand / capacity balancing

In nearly all (bio)pharmaceutical companies, the management of Technical Operations is faced with questions like the following:

- Can we cope with demand volume at attractive costs in the long-term?

- Are we able to fulfill all demands considering the high number of new products incl. their volatility in timing and volume?

- Are we able to manage tender business?

- In which technologies do we have to invest? – and at which locations / in which regions?

- At what point in time do we need to initiate major investments?

- What is our risk management concept for key products / key markets? – and what does that mean for our site network?

- Should we better or additionally intensify CMO involvement?

- Will our current site network set-up (still) be the right one? – how do we answer to local market access, PPP requirements, increasing cost pressure?

- Where should we set the focus of optimization initiatives? …

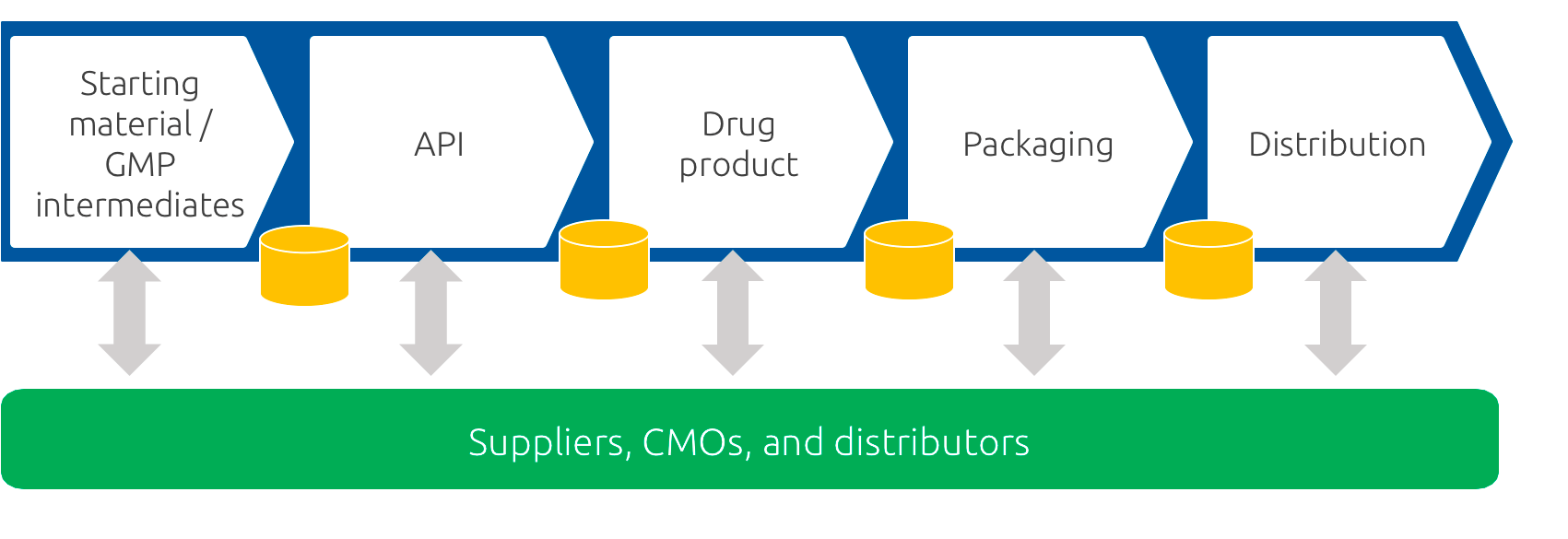

We at JSC are able to answer these questions and to plan the main processes for drug substance production, drug product and packaging incl. their sub-processes.

We are able to perform such planning activities for small as well as large molecules considering the different process steps and knowing their specifics regarding performance, throughput time and yield.

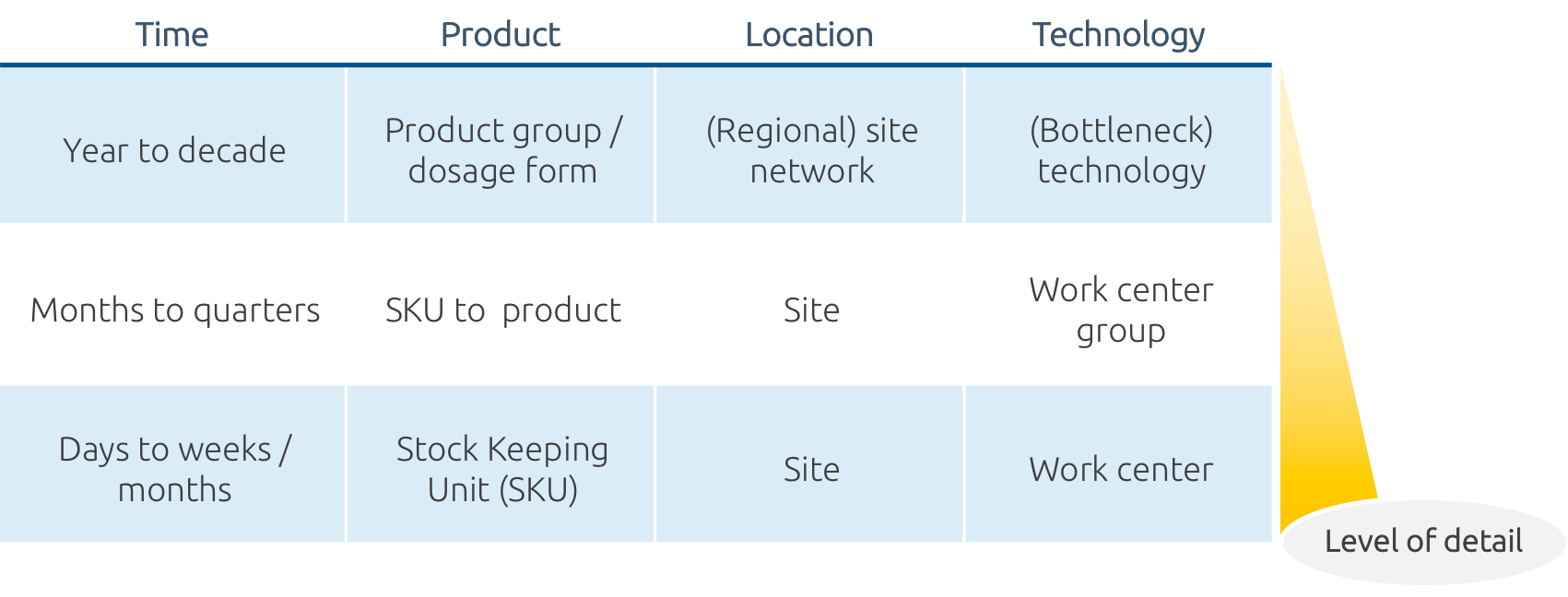

Planning can be done for an entire plant network, a single site or selected products and / or technologies – time perspective ranges from one year to 25 years and time cycle from months / quarters to years.

The level of detail / aggregation depends on the project scope and can go down to SKU level incl. product components – with and w/o consideration of inventory.

JSC’s approach in the long-term planning process follows 4 guiding principles:

- The future is uncertain and markets are volatile – i.e. think in demand / capacity scenarios especially regarding the long-term time horizon …

- …but also understand the sensitive levers regarding each analyzed scenario

- Be complete – consider all demand types (market, CTS, contingency, pipeline filling), all internal and external sites (CMOs)

- Follow the KISS principle – i.e. use the right level of aggregation regarding products and technologies

- Focus on potential bottleneck technologies along the relevant end-to-end supply chain

- Reflect process improvements, new equipment, and overall allocation constraints

- The corresponding IT system is for the user – not the other way around

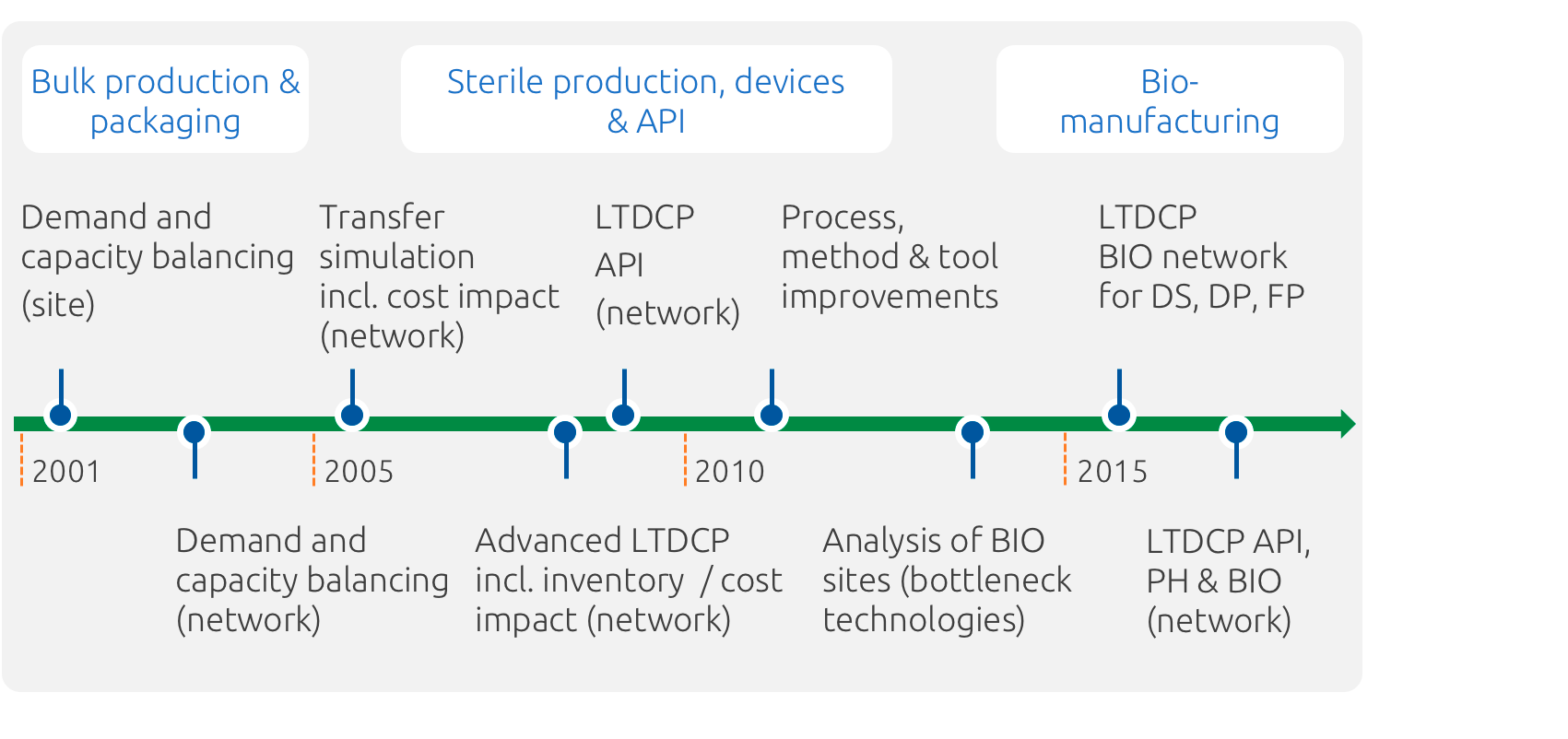

During the past 15 years, JSC has worked on long-term demand and capacity planning models and procedures for a variety of top 30 pharmaceutical companies.

API Contingency Concept – JSC worked with one of the top global pharma companies to enhance its contingency planning for API supply